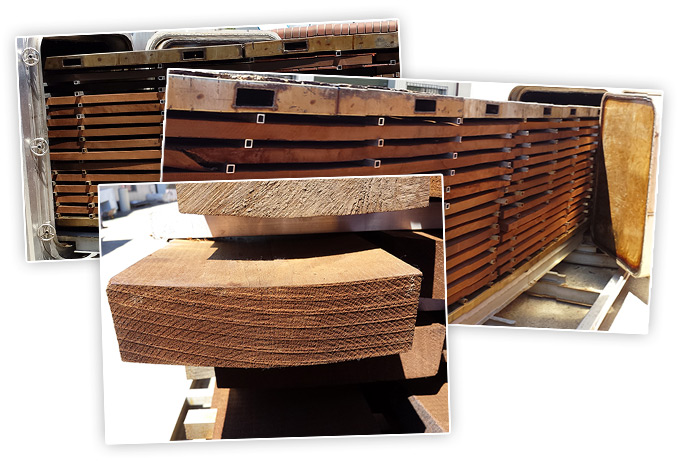

Thermowood

Long-standing research allowed for development of technology for thermal wood processing what resulted in creation of the chamber for anaerobic wood heating.

Wood processing is optimised for specific kind and thickness of wood and lasts for about 48 h.

In order to avoid cracks and discolorations, material dried to 8% humidity is required, which allows for obtaining homogeneous humidity and colour on the wood surface. Wood colour is obtained in a natural way, without the use of chemicals.

Thermally modified wood is characterised by the resistance to humidity and dimensional stability, what offers new possibilities of its use inside and outside buildings.