System control

EKOPOL 1 automatic control system is designed for automatic wood drying in drying as well as steaming chambers. It ensures optimal drainage of material due to strict compliance with parameters.

Properties of the dryer controller:

- easy handling,

- modern and fully digital control system,

- simple and intuitive work programming process of dryer(s)

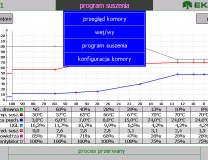

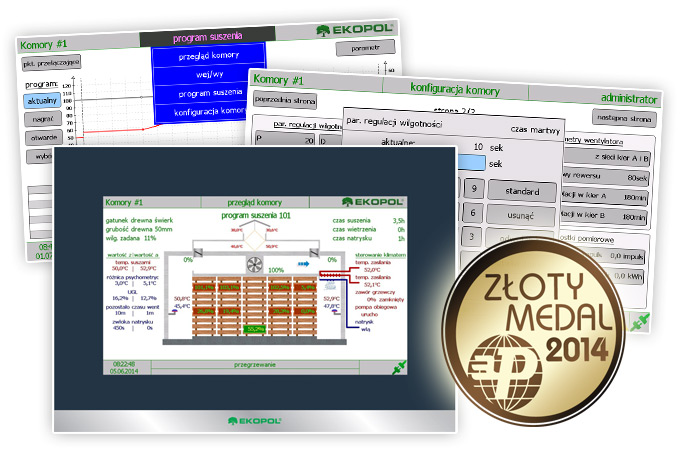

- full visualization of technological processes on the color 10.2” touchscreen,

indicating not only current values but also the process as a whole, - easy way to connect with modern mobile devices (notebook, tablet, smartphone, etc.) and control

process with their use, - presents drying algorithms in a user-friendly form, both with the use of tables and color charts in

order to facilitate rapid analysis, - displays all the current parameters of the dryer in real time

- displays the status of all executing devices,

- supervises and controls the work of all executive devices,

- automatically eliminates erroneous readings from improperly connected probes,

- optimizes the use of electricity by adjusting the speed and direction of fan rotation to the dried

material, - optimizes the use of thermal energy by adjusting the flow of the heating medium to the energy

requirements of the dryer,

The work of drying chamber may be controlled remotely with the use of different devices connected to wireless or company network (PC, tablet, smartphone). When the process is finished, the system may send an e-mail with drying report. It may also indicate potential errors and send them by e-mail.

The net allows for charts downloading, modification of device’s configuration and even software updating. Basic information on materials dried and current drying process are showed on the screen. As a result, the action review may be done immediately. Basic parameters are green. These are: wood kind, thickness, desired humidity level and time of drying as well as the total time of chimney and sprinkles work. Main parameters of climate control are on the left side. It is enough to compare desired values with currently measured ones in order to check whether there are not any problems. Drying programme is displayed in the form of a table.

The system automatically separates the successive drying phases depending on the wood humidity. By pressing any columns, the user gets their enlargement and may modify parameters, which he or she is interested in (psychometric difference - drying gradient, air humidity as well as UGL are parameters which depend on one another. Modifying one of them results in a change of the rest). The upper half of the screen may be used in order to get a graphic representation of drying algorithm or display other parameters of drying programme. Any modifications may be introduced only if the entitling code is entered previously. The current programme may be modified or other programmes may be developed during drying (programming and drying are done independently)

Visualizing

The drying algorithm can be presented with the use of both tables and color charts in order to facilitate rapid analysis. As compared to the old control systems, architecture of the current control system is less schematic. If the user has three drying rooms, they may use any number of screens. A drier standing by the drying plant no. 2 is able to switch the screen to another drying room once he has checked the previous chamber - all this without moving. It is possible that two separate screens will correspond to the control of a single drying plant (one in the drying plant itself, the other at the manager's office). In addition,

it is also possible for the drying plant to work without a screen; the dryer, can control the process from any chamber with the use of their smartphone.Data stored in the programmer enable to create characteristics of the drying process for almost all types of wood found in Poland. Such data are called drying programmes (dry curves). The user can choose from a few standard drying programmes for each type of wood.

The software is in Polish, English, German and Russian language.